Lump Crusher Parts and Manufacturer

Posted on January 5th, 2017 by RWM Admin

The lump crushers are typically designed as a module located at the feed point of a conveyor or elevator and at the discharge point of a dryer, granulator, or mixer to produce minus ½” to 3” nominal sized material. The crusher casing is a rectangular steel box containing a square horizontal shaft with hardened alloy steel blades oriented on the shaft in a spiral pattern which mesh with a bottom sizing bar grid. The upper section of the housing will have a sloped bar scalping grizzly or a solid sloped plate to channel the feed material into the path of the crushing blades. Typically the crushing blades are of a hooked tooth design allowing the size reduction of lumps having a maximum nominal dimension of 20” without choking or stalling the crusher.

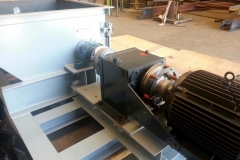

The lump crushers are driven with direct drive configuration consisting of a concentric shaft speed reducer coupled directly to the crusher shaft and an electric drive motor. To minimize equipment maintenance, no drive belts or chains are used in the crusher drive train. Power requirements for crushers would range from 10 to 60 hp depending on the design capacity required.

Lump crushers are designed for coarse size reduction of dense solidified material or breaking of lumps of conglomerated granular materials. These units are capable of processing material flows of 10 to 300 tph. The units are designed as a single piece of equipment with the crusher housing and drive train mounted on a common structural base frame. The crushers function at relatively slow operating speeds (less than 150 rpm); therefore, air and dust evacuation are not typically an issue.

Lump Crushers Gallery